As I explained in my most recent newsletter (what do you mean, you’re not a subscriber? Get thee hence and rectify matters immediately! I’ll wait… https://tinyletter.com/TheFreezoneCollective) I have made a book.

I have made a book, as in the physical object, rather than the words that go in one, although I did that too. And I rather enjoyed it. Possibly a little too much. And it’s got me thinking. Let me explain.

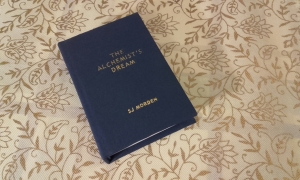

I made a book for my wife’s Christmas present. I made a clothbound A6-sized hardback book, nearly 300 pages long, hand-sewn and glued, with headbands and a ribbon, of The Alchemist’s Dream. You could conceivably argue that deciding early November that this is what I was going to do, from scratch, with only the faintest idea of how to accomplish the task, is the very epitome of hubris, you’d probably be right. But being an author and hubris are pretty much synonymous anyway, so although I was making a huge leap in the dark, it’s a journey I’ve made many times before. Although failure was always an option (never let anyone tell you otherwise), I’d be leaving enough time for a Plan B.

my wife’s Christmas present. I made a clothbound A6-sized hardback book, nearly 300 pages long, hand-sewn and glued, with headbands and a ribbon, of The Alchemist’s Dream. You could conceivably argue that deciding early November that this is what I was going to do, from scratch, with only the faintest idea of how to accomplish the task, is the very epitome of hubris, you’d probably be right. But being an author and hubris are pretty much synonymous anyway, so although I was making a huge leap in the dark, it’s a journey I’ve made many times before. Although failure was always an option (never let anyone tell you otherwise), I’d be leaving enough time for a Plan B.

In the event, I made three books, each one progressively more competent than the previous one, and finally decided that the last was present-worthy.

In the process, I realised two things. Firstly, it confirmed to me that ‘desktop publishing’, as promised so long ago, is genuinely possible – in that I can own every stage in production, from writing the words, laying out the manuscript, printing the pages, to constructing the finished article from card and paper and cloth. Secondly, that I loved doing it. There’s something so incredibly satisfying, and so incredibly slow, about making one book at a time.

The firstly bit first. Desktop publishing (hereafter DTP) has been a thing for nearly fifty years, but mostly in the context of producing electronic files to be sent to a printer, as opposed to the printer setting up typeface from a piece of copy. I did exactly that when I was editor of the BSFA’s Focus magazine – producing Encapsulated Postscript for the whole magazine, and dropping it onto the printer’s FTP server. But before then, samizdat (translated, it means (more or less) ‘self published’) in the Soviet Union, and then earlier still – pamphlets and treatise have always been printed and distributed by hand, and of course and obviously, before Gutenberg, before printing was even a thing, all books were handwritten and handmade, often in a monastery’s scriptorium. They were things of inexpressible value. It’s something I’ve tried to convey in Arcanum, the rarity, the enormity of books.

Technology has moved on. The really long part of making a book, the creation of the words, is still as painstaking as ever, but the copying of the script I can delegate to my desktop printer. I can press a button and assuming it’s got enough paper, it’ll print – both sides and in order – all the pages without further intervention from me. It’s a decent printer, too: I’m not restricted to black and white, it’ll do spot colour, but also, at any point in the text, I can insert pictures, full colour. The typesetting, the choice and size of font, everything like that is an artistic/aesthetic decision for me.

Then it’s back to the age-old techniques of cutting, collating, and folding the pages, usually into collections of four leaves (called signatures), then sewing them together using one of many various techniques to form a signature block. Which then needs glueing and endpapers and trimming to form a flat edge to make it easy to turn the pages. This last stage is particularly difficult without access to an industrial guillotine or some really very fancy equipment, but it is doable.

And that’s kind of the point. To make books without buying in huge pieces of machinery, using things that I already have lying around the house. My book press is a sheet of MDF cut in half and joined using four bolts and wingnuts. Obviously, I’ve made concessions. If I’m going to put titles on the covers, then I’m going to need some form of cloth-printing technology – I’ve experimented with both heat-activated powders and hot foil – but that’s not actually that expensive, and is more time-consuming, which is fine. I can buy book cloth, and I can buy the headbands (the little bits which obscure the folds in the signature block), but I can make book cloth using just material and iron-on backing, and the headbands out of old curtain material and spare shoelaces. The card for the covers is 3mm greyboard (commonly used for framing pictures and really very cheap). The cloth comes from end-bins and remnants. At some point I’d like to try leather, plether, and wood, but that’s for future projects.

And that’s kind of the point. To make books without buying in huge pieces of machinery, using things that I already have lying around the house. My book press is a sheet of MDF cut in half and joined using four bolts and wingnuts. Obviously, I’ve made concessions. If I’m going to put titles on the covers, then I’m going to need some form of cloth-printing technology – I’ve experimented with both heat-activated powders and hot foil – but that’s not actually that expensive, and is more time-consuming, which is fine. I can buy book cloth, and I can buy the headbands (the little bits which obscure the folds in the signature block), but I can make book cloth using just material and iron-on backing, and the headbands out of old curtain material and spare shoelaces. The card for the covers is 3mm greyboard (commonly used for framing pictures and really very cheap). The cloth comes from end-bins and remnants. At some point I’d like to try leather, plether, and wood, but that’s for future projects.

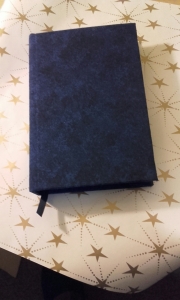

The finished product is, by necessity, homemade. It’s not professional: the cloth isn’t varnished or coated in any way (though I’ll try that at some point), the finishing is … slightly rustic in places. But it’s still something. It has a proper heft to it. A charm, if you will, in an age of mass-production.

The finished product is, by necessity, homemade. It’s not professional: the cloth isn’t varnished or coated in any way (though I’ll try that at some point), the finishing is … slightly rustic in places. But it’s still something. It has a proper heft to it. A charm, if you will, in an age of mass-production.

And this is where we get on to the secondly. There’s an awful lot I need to learn, and in learning, become good at it. Ultimately, I could see myself offering it as both an outlet for those books of mine which are out-of-print, or so wildly uncommercial that they’d never otherwise see the light of day, and for (extremely) limited editions of other writers’ work – limited, in that I could as easily produce just one copy as I could five. Gifts. Presentation copies. Things like that.

The only slight hesitation I have is that the cost per copy won’t be cheap: the printing is a substantial part of the cost, even (or especially because) using an inkjet printer, then the cloth, the board, the paper, the ribbons… the price of the raw materials does add up. Then there’s the time – the collating, folding, sewing, gluing, ironing, pressing… I need to start calculating exactly how long I spend on a single book and factor that in to a final, realistic price.

The only slight hesitation I have is that the cost per copy won’t be cheap: the printing is a substantial part of the cost, even (or especially because) using an inkjet printer, then the cloth, the board, the paper, the ribbons… the price of the raw materials does add up. Then there’s the time – the collating, folding, sewing, gluing, ironing, pressing… I need to start calculating exactly how long I spend on a single book and factor that in to a final, realistic price.

And even if it’s not something that turns out to be at all commercial – and why does it have to be? – it’s still something I want to do. The finished product, a handmade, hand-cut, hand-sewn, hardback book, was so wonderfully tactile that I know that I just want to do it again, to practice and get better and use different techniques to get different finishes and effects.

If this is inexplicably the birth of new venture, something to do as well as writing, then yes, and gladly.

Comments

Ginny